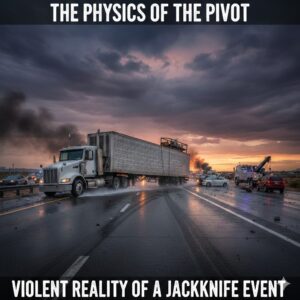

Seeing a massive tractor-trailer begin to fold in on itself is one of the most terrifying sights a motorist can encounter on the open highway. The sheer scale of the machinery makes the movement look like a slow-motion disaster, yet the energy involved is incredibly violent and destructive. What starts as a simple loss of traction can quickly escalate into a catastrophic event that shuts down several lanes of traffic for hours.

The mechanical relationship between the cab and the trailer is based on a delicate balance of tension and friction. When these forces are in harmony, the rig moves as a single unit, following the driver’s steering inputs with predictable precision. However, when the trailer loses its alignment with the tractor, the pivot point at the fifth wheel becomes a liability instead of a tool for maneuverability.

This specific type of mechanical failure occurs when the trailer swings forward while the cab slows down or stops abruptly. It creates a V-shape that resembles the folding action of a pocket knife, which is why experts refer to it as a jackknife. Understanding the physics of a jackknife accident and what’s behind this sudden loss of control is essential for anyone trying to navigate the aftermath of a commercial trucking collision.

The Braking Imbalance

The primary catalyst for a trailer swing is an imbalance in the braking force applied to the various axles of the heavy rig. When a driver slams on the brakes in an emergency, the drive axles of the tractor can lock up while the trailer continues to push forward with its own massive momentum. This creates a situation where the rear of the vehicle is moving faster than the front, leading to an inevitable collision between the two parts.

Modern anti-lock braking systems are designed to prevent this exact scenario by modulating the pressure to each wheel, but mechanical failures can still occur. If the trailer brakes are poorly maintained or if the load is not distributed correctly, the risk of a pivot increases exponentially. The tractor acts as an anchor that the trailer simply tries to push out of the way as it slides sideways across the asphalt.

Once the drive wheels lose their grip on the road, the tractor no longer has the lateral stability required to keep the trailer in line. The fifth wheel connection allows for rotation, which is necessary for making turns but deadly when the trailer starts to overtake the cab. The entire rig becomes a giant unguided projectile that ignores the driver’s desperate attempts to regain steering control or stop the forward progress.

Environmental Triggers

Weather plays a significant role in reducing the friction needed to keep a heavy trailer tracking straight behind the tractor. In desert climates, sudden downpours can lift oils and dust from the road surface, creating a slick layer that acts like ice under the heavy tires. Even a small amount of moisture can be enough to trigger a slide if the driver is carrying a light load or traveling at high speeds.

Arizona motorists often deal with unique hazards like icy Scottsdale roads during winter cold snaps or the intense flooding of monsoon season. These conditions make it difficult for the tires to maintain a consistent bite on the pavement, especially during downhill descents or sharp curves. A driver who fails to adjust their speed for these environmental shifts is inviting a loss of control that can end in tragedy.

Friction is the only thing standing between a safe journey and a high-speed slide that destroys everything in its path. When the road surface becomes compromised by water or debris, the margin for error for a commercial trucker narrows to almost zero. The lack of lateral resistance allows the trailer to drift out of its lane, initiating the first stage of a fold that most drivers cannot stop.

High Speed Momentum

There is a specific moment during a trailer swing that experts call the point of no return. This happens when the angle between the cab and the trailer becomes so acute that no amount of steering or braking can pull the rig back into a straight line. At this stage, the physics of momentum take over completely, and the driver becomes a passenger in their own vehicle while waiting for the impact.

Recovering from a partial slide requires a level of precision and calm that is difficult to maintain in the heat of a crisis. If the driver overcorrects or panics by applying more brake pressure, they often accelerate the folding process instead of stopping it. The energy of the moving trailer is so immense that it can easily flip the tractor over or crush the cab against a concrete barrier.

High-speed travel on interstates amplifies every mistake and mechanical flaw, turning a minor skid into a life-altering disaster. The force generated by a forty-ton trailer moving at highway speeds is enough to punch through steel guardrails and bridge supports. Once the momentum moves away from the center of the lane, the destructive potential of the rig is limited only by the objects it eventually hits.

Multi Lane Collisions

A swinging trailer acts like a massive scythe that sweeps across multiple lanes of traffic, leaving other motorists with nowhere to go. Because the rig is folding in on itself, it occupies a much larger footprint on the road than a standard vehicle ever would. Drivers in adjacent lanes are often trapped between the sliding trailer and the median, making a collision virtually impossible to avoid.

The resulting pileups often involve several passenger vehicles that are caught in the wide arc of the trailer’s path. These impacts are especially dangerous because they occur at unusual angles, often striking the sides or roofs of smaller cars. The trailer becomes a solid wall of steel that blocks the entire highway, creating a secondary risk of rear-end collisions from following traffic that cannot see the hazard.

Cleaning up the wreckage of a multi-lane event requires specialized heavy-lift equipment and hours of forensic investigation. The debris field can stretch for hundreds of yards, containing parts from several different vehicles and potentially hazardous cargo from the trailer. It is a scene of total chaos that demonstrates the terrifying power of a heavy rig that has lost its mechanical and physical equilibrium.

Conclusion

Preventing these violent events requires a combination of strict maintenance protocols and advanced driver training programs. A rig that is kept in peak condition with properly adjusted brakes is much less likely to experience a catastrophic pivot during an emergency stop. Companies must prioritize these safety checks to protect their drivers and the public from the reality of a mechanical failure on the road.

Technology like electronic stability control and collision mitigation systems are becoming standard in the industry to help bridge the gap between human reflex and physical reality. These tools can detect the early signs of a trailer swing and apply corrective measures before the driver even realizes there is a problem. However, no piece of software can replace the value of a cautious and well-trained operator behind the wheel.

A professional investigation into the cause of a crash is the only way to determine if the event was truly unavoidable or the result of negligence. Looking at the tire marks and the data logs from the truck provides the evidence needed to hold the responsible parties accountable. Every incident offers a lesson in physics and safety that can be used to prevent the next tragedy on the highway.